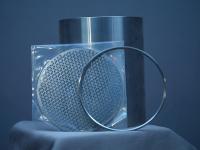

Master Vapor Pumps Classic MVP6CFM

MODEL MVP-6CFM

The most valuable pump for solvent extraction processing

FEATURES & BENEFITS:

Certified system gas recovery pump

Positive displacement LP-Gas extraction pump

Electric powered double diaphragm gas compressor

Designed especially for LP-Gas vapor recovery

Will also pull deep vacuum in chambers

Ideal for butane and butane/propane mix vapor recovery processes

Recovers 100% propane vapor when used with recovery tank cooling

Can pull vacuum back through the pump when evacuating a system

Passes liquid condensation without damage

Explosion-proof motor rated for C1D1 areas

Three-phase and single-phase models available

Continuous 100% duty cycle – run 24/7

No air compressor needed

Patented pump drive technology

No rotating or moving seals

Can run dry without damage

Can stall under pressure without damage

Can start against full load and pressure

No driving air used; cannot leak air into the system

Maximum pumping pressure output is adjustable

No lubrication in the pump heads; no contamination of product

Meets NFPA 58 requirements for LP-Gas – rated LPG 350 PSI

Compliant with NFPA and UL standards for C1D1 motors and LPG vapor recovery

Meets Class 1 Division 1 hazardous area facility requirements (when installed correctly)

Three-phase motors compatible with VFD (variable frequency drive) for speed control of pumping

Easy DIY diaphragm replacement or internal cleaning when needed

Simple DIY stainless steel reed valve replacement if ever needed

One year manufacturer’s warranty (see Operation Manual)

Made in the USA

PERFORMANCE FACTOIDS:

Recover LP-Gas vapor at OVER 6 CFM (cubic feet per minute)

Recover butane at up to 1 LB/MIN (pounds per minute)

Recover and recondense butane at OVER 12 GPH (gallons per hour)

Maximum pumping outlet pressure: 60 PSI (4.1 bar) continuous; 70 PSI (4.8 bar) intermittent

Maximum pumping inlet vacuum produced: 27 InHg (0.91 bar)

Maximum pumping speed: 190 CPM (cycles per minute)

Pump static withstand pressure rating: MAWP 350 PSI (24 bar)

Materials: pressure section: stainless steel; diaphragms: FKM; reed valves: stainless steel

Optional PTFE diaphragms kit available

Process gas temperature range: FKM -40°-275°F (-40°-135°C); PTFE +40°-220°F (4°-104°C)

Recommended FKM replacement schedule: every 1000 hours running time

Air temperature range for motor/gearbox operation: 32°-104°F (0°-40°C)

PUMP HEAD CHARGE:

Motor is coupled to diaphragms with patented gas pressure charged chamber

Pumping outlet pressure runs about 10 PSI lower than the charge gas pressure level

Non-reactive CO2 gas is used to charge the pump head

CO2 gas is safer than air for driving the pumping

CO2 gas is non-flammable and non-explosive with LPG (should a diaphragm ever leak)

CO2 gas regulator with gauges is provided with pump assembly

CO2 tank is operator provided (cannot ship filled tanks) – from any welding supply shop

Pump charge gas supply: standard (#20) 5 LB tank of industrial CO2

Typical CO2 gas usage: <0.2 SCFH (very little); estimated life of charge gas tank: 1 year

Pump charge gas pressure range: continuous 5 to 70 PSI (1.4 to 5.5 bar); to 80 PSI intermittent

ELECTRICAL & MECHANICAL:

Electric motor: explosion proof for C1D1 hazardous areas; rated Class I Gr C & D, Class II Gr F&G

Electric motor: 1 HP, 1800 RPM, 60 HZ

Motor option: Model MVP-6CFM-1PH: Single-phase: 115/208-230V, 13.4/6.7 FLA (full load amps)

Motor option: Model MVP-6CFM-3PH: Three-phase: 208-230/460V, 3.3/1.65 FLA, Inverter-rated

Pump speed: 190 CPM (cycles per minute) at 60 HZ

Noise: sound pressure measured 1 meter from pump: 80.5 dBa

Porting: process inlet and outlet: 1/2" JIC-male

Added ports for optional pressure gauges: inlet and outlet: 1/4" FNPT

Inlet & outlet ports at ideal equipment connection heights 46” and 41” above floor

Size: 17.0” x 19.9” base x 46” tall; minimum use of valuable floor space

Weight: 182.5 lb (82.8 kg)

Be the first!

Call for Pricing & Availability707-923-9319

Customer Reviews

Be the first!