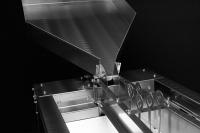

Munch Machine Double Mother Bucker

Professionally engineered with the highest quality parts, our harvesting equipment provides years of reliable service with minimal maintenance.

The Mother Bucker was developed after 75 years manufacturing harvesting and processing equipment for the hops industry.

MUNCH Machine is introducing industrial-grade farm equipment to the cannabis industry. With generations as the global leader in hops harvesting, we know better than anyone that down-time during harvest is not an option. Our machines are tough, reliable, built to last, and designed to process at the scale of the emerging cannabis industry.

Operation of the Mother Bucker is simple yet effective. Insert a stem in the appropriately sized die hole and the machine pulls it through, gently removing flowers from perfectly stripped stems. Variable speed control allows for versatility - slow the machine down for damage-free bucking of carefully dried plants, or speed it up for rapid bucking of freshly harvested stems. One machine for all your bucking needs: wet or dry.

Munch Machine Mother Bucker Benefits

The Mother Bucker can harvest up to 300 pounds per hour with the Double Bucker. It's incredibly versatile, and can buck wet or dry. Easy clean up in less than 10 minutes so you can wrap up a long day of harvest quickly.

It is constructed from food grade stainless steel and powder coated surfaces are durable and easy to clean. It features high-quality SealMaster bearings and Sumitomo Hyponic gearmotor.

The Munch Machine Mother Bucker is proudly made in the USA, with patents pending

Hear that? Neither did we. This machine operates incredibly quietly, and features forward and reverse operation to easily clear blockage. Munch Machine kept the operateros well-being top of mind when designing the machine, adding a safety kill switch to ensure user safety. Both machines plug into a standard 110 volt, 20 amp circuit.

Multiple die holes match different diameter stems for perfect stripping, so regardless of how thick your stems are, you can buck fast. Designed to integrate with conveyor belts and trimmers.

Mother Bucker Indoor vs. Outdoor

Indoor and outdoor versions differ by the wheel-set only, the outdoor unit will have the 8" flat free tires designed for off-road use, and the indoor will have 360° swivel casters designed for hard surfaces.

So whether you are brining your harvest to a warehouse, or need to bring your bucking machine out to your harvest, you can do easily.

Munch Machine Double Bucker Features

Variable speed control allows for damage free bucking of both wet and dry material.

Capable of processing 300lbs (wet) per hour, 76lbs (dry) per hour

Industrial grade, 100% serviceable, 100% rebuild able

Built from structural grade A36, A500, and 304 Stainless steel to last for generations

Designed to integrate perfectly with cGMP Compliant facilities

Silent operation

Runs on Standard 110V / 20A Circuit

Process stems up to ¾” diameter - Interchangeable die plates to accommodate all types of material

Reduces labor costs and saves time

5-year manufacturer defects warranty

Emergency stop switch

Forward and momentary reverse directional switch

Designed to be used with conveyor systems or bin catchment systems

25’ industrial grade plug

Components: ½ hp Lenze motor and VFD drive, Seal Master bearings, Wrap flex coupler, 1.25” Steel drive shafts

Good Manufacturing Practices (GMP):

All The Components On The Double Bucker Are Designed To Fit In A cGMP Compliant Workflow

Motor utilizes FDA approved lubricant

Powder coat has FDA certification

Neoprene rollers have FDA certification

Stainless Steel Face Plate has FDA certification

Munch Machine Mother Bucker Warranty:

5 Year Warranty On Any Manufacturer Defects

These Buckers are 100% serviceable

All Parts Stocked

Power Requirements:

110 Volt

Requires Dedicated 20Amp Circuit

Cleaning:

Once Daily,Takes 15-20 min

Stiff Brush and 70% Rubbing Alcohol

Can be Power Washed

Call for Pricing & Availability707-923-9319

Customer Reviews

- Colin roseGothic entertainment

- Luis CalderonGreen Horizons